Railway Manufacturing

CREW Railway Manufacturing Vision

By 2025, We aim to design, develop and produce Light weight, technologically superior Rail Coaches / Cars indigenously as per ‘Make in India’ program and that will be of World Class, Products & Services ensuring Quality & Safety, adding strength to Rail Industry.

Mission @ CREW Railway Manufacturing

- Ensuring application of modern technology at par with global standards

- Carry out Research and Development for cost effective / innovative products.

- Establishing well defined Goals in our business approach.

- Enhancement of the internal systems and standards for quality deliverables in time.

- Adapting the Organization open for technological improvement.

- Adapting best quality materials and services.

CORE ACTIVITIES – The Complete Diversification

We commit ourselves to achieve excellence in the followings areas

- Design, Manufacture, Supply, Integration, Furnishing and Commissioning of Rail Coaches, Products and Rail Systems.

- Execution of bulk material handling projects on EPC and BOO. Also service provider for Operation & Maintenance.

- Manufacture & Supply of various Material Handling equipments.

- Coal unloading and transportation in major ports in India and Fujairah (UAE)

- Coal mining covering Excavation, Crushing, Storing, and Transportation.

| Major Machinery | Testing Equipment |

|---|

| Auto Aligned Laser Welding | Spectrometer |

| Robotic Spot Welding | Universal Testing Machine |

| Laser Cutting Machine |

Non Destructive Testing Facility

a) Dye penetrant

b) Magnetic Particle

c) Ultrasonic |

| CNC Plasma Cutting | Digital microscope for macro testing. |

| Semi-Automatic Spot Welding | Vickers Cum Brinell Hardness testing |

| CRF Line | High Voltage Tester. |

| Press brake | Megger (500/100 Volt DC) |

| Shearing | Continuity Tester (10 point with expandable ports) |

| MFDC IT Gun Spot welding | Kelvin Double Bridge |

| Radial Drilling | Flexible Tester as per IEC 61386 |

| 5 in 1 Iron Worker | Impact Tester as per IEC 61386 |

| CNC Turning Centre | Fire Retardant test chamber |

| Lathe | |

| Bandsaw cutting | |

| RTIG Welding | |

| MIG Welding | |

PRODUCT PORTFOLIO

Our involvement in major types of coach cater to

- Long Running Conventional Trains

- Intercity Trains

- Sub – Urban Trains

- Vande Bharat Express

Rail Products in our range of production

- Complete Rail Coach Shell / Car Body

- Under-frame / Under Car Assembly

- Sidewall Assembly

- Roof Assembly

- End wall Assembly

- Cable Tray and Duct assembly

- Front Part Assembly

- End Part Assembly

- Bogie Bolster

- Bogie frame

- Partition Frames

- Door Cut out Assembly

- Seat and Berth

- All Types of Sliding Doors

- All Types of Luggage Racks

- Sidewall Panel, Roof & Flooring

- Fuel Tank

- Water Tank

- Cable Harness

- Switch Board Cabinet (RDSO Approved)

- Sidewall Panelling & Wiring

- Control Panel

- Transformers

- Set of Panel (HV, LV, RBC)

- Battery Box

- Capacitor bank

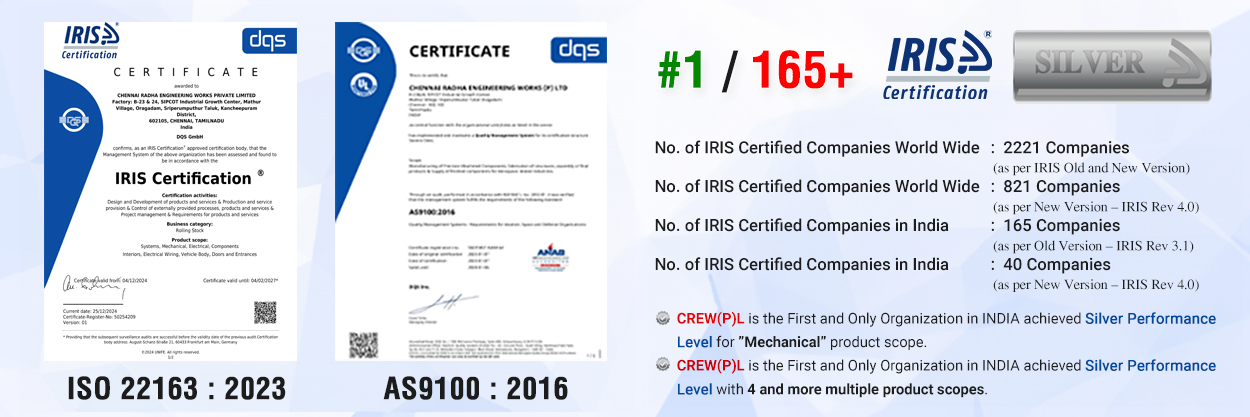

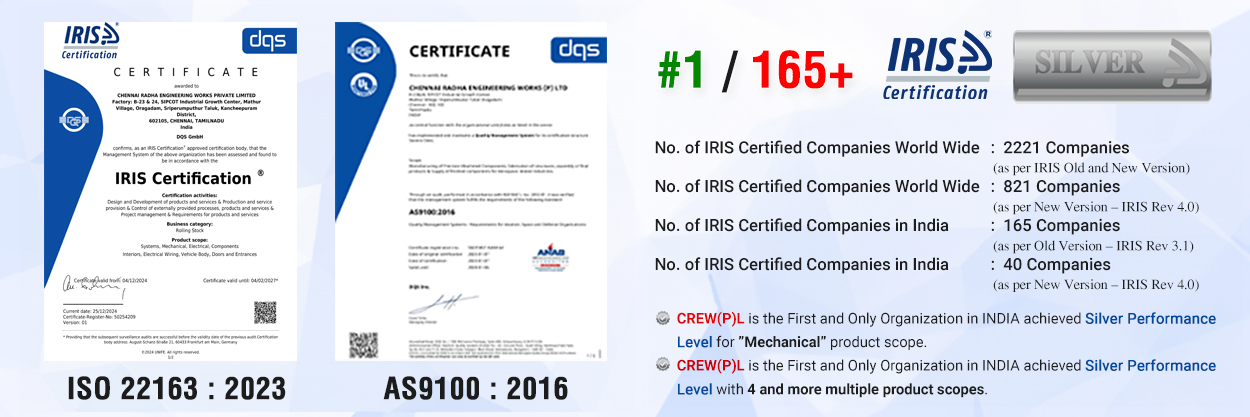

KEY CLIENTS / CERTIFICATIONS

FURNISHING ACTIVITIES

We offer complete Mechanical and Electrical furnishing for various types of coaches at client premises. Our electrical furnishing works covers for about 2/3rd among the total production of Rail Coaches by ICF.

The various types of coaches for Mechanical and Electrical Furnishing are:

- Complete Rail Coach Shell / Car Body

- Diesel Electric Tower Car (DETC)

- Military Langar

- DEMU IGBT Trailer

- SV/DPC (Spart)

- ARMVAC (Spart)

- ARTV (Spart)

- LWLRRM (LHB Power Car)

- LSLRD

- LHB

- LWCBAC

- LWSCZ

- ANTODAYA

The major Furnishing works carried out by CREW are as follows

- Complete interior mechanical and electrical furnishing works

- Load test and performance

- Engine and alternator alignment

- Hydraulic & coolant pipe line fabrication and erection

Apart from furnishing, we also carry out the Installation, Commissioning and test run of the Diesel Engine systems and accessories for DETC.

ANNUAL PRODUCTION CAPACITY